Steve Clean The Semiconductor Ecosystem – Defined

[ad_1]

The final yr has seen a ton written concerning the semiconductor business: chip shortages, the CHIPS Act, our dependence on Taiwan and TSMC, China, and so on.

However regardless of all this speak about chips and semiconductors, few perceive how the business is structured. I’ve discovered one of the simplest ways to grasp one thing sophisticated is to diagram it out, step-by-step. So right here’s a fast pictorial tutorial on how the business works.

The Semiconductor Ecosystem

We’re seeing the digital transformation of all the things. Semiconductors – chips that course of digital info — are in virtually all the things: computer systems, vehicles, residence home equipment, medical gear, and so on. Semiconductor firms will promote $600 billion value of chips this yr.

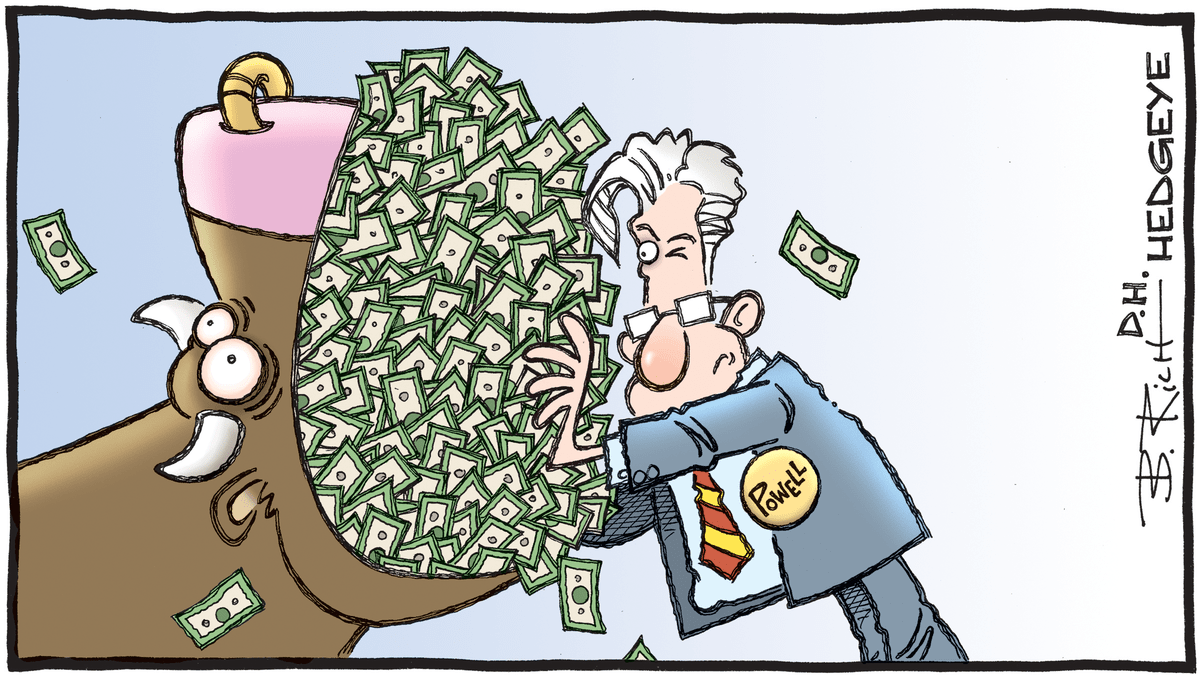

Wanting on the determine under, the business appears fairly easy. Firms within the semiconductor ecosystem make chips (the triangle on the left) and promote them to firms and authorities businesses (on the appropriate). These firms and authorities businesses then design the chips into techniques and units (e.g. iPhones, PCs, airplanes, cloud computing, and so on.), and promote them to shoppers, companies, and governments. The income of merchandise that comprise chips is value tens of trillions of {dollars}.

But, given how massive it’s, the business stays a thriller to most. For those who do consider the semiconductor business in any respect, chances are you’ll image employees in bunny fits in a fab clear room (the chip manufacturing facility) holding a 12” wafer. But it’s a enterprise that manipulates supplies an atom at a time and its factories value 10s of billions of {dollars} to construct. (By the way in which, that wafer has two trillion transistors on it.)

For those who have been capable of look inside the easy triangle representing the semiconductor business, as a substitute of a single firm making chips, you’d discover an business with lots of of firms, all depending on one another. Taken as an entire it’s fairly overwhelming, so let’s describe one a part of the ecosystem at a time. (Warning – this can be a simplified view of a really complicated business.)

Semiconductor Business Segments

The semiconductor business has seven several types of firms. Every of those distinct business segments feeds its assets up the worth chain to the following till lastly a chip manufacturing facility (a “Fab”) has all of the designs, gear, and supplies essential to manufacture a chip. Taken from the underside up these semiconductor business segments are:

- Chip Mental Property (IP) Cores

- Digital Design Automation (EDA) Instruments

- Specialised Supplies

- Wafer Fab Gear (WFE)

- “Fabless” Chip Firms

- Built-in Gadget Producers (IDMs)

- Chip Foundries

- Outsourced Semiconductor Meeting and Take a look at (OSAT)

The next sections under present extra element about every of those eight semiconductor business segments.

Chip Mental Property (IP) Cores

- The design of a chip could also be owned by a single firm, or…

- Some firms license their chip designs – as software program constructing blocks, known as IP Cores – for broad use

- There are over 150 firms that promote chip IP Cores

- For instance, Apple licenses IP Cores from ARM as a constructing block of their microprocessors of their iPhones and Computer systems

![]()

Digital Design Automation (EDA) Instruments

- Engineers design chips (including their very own designs on high of any IP cores they’ve purchased) utilizing specialised Digital Design Automation (EDA) software program

- The business is dominated by three U.S. distributors – Cadence, Mentor (now a part of Siemens) and Synopsys

- It takes a big engineering staff utilizing these EDA instruments 2-3 years to design a fancy logic chip like a microprocessor used inside a telephone, pc or server. (See the determine of the design course of under.)

![]()

- As we speak, as logic chips proceed to turn into extra complicated, all Digital Design Automation firms are starting to insert Synthetic Intelligence aids to automate and pace up the method

Specialised Supplies and Chemical substances

To this point our chip continues to be in software program. However to show it into one thing tangible we’re going to should bodily produce it in a chip manufacturing facility known as a “fab.” The factories that make chips want to purchase specialised supplies and chemical substances:

- Silicon wafers – and to make these they want crystal rising furnaces

- Over 100 Gases are used – bulk gases (oxygen, nitrogen, carbon dioxide, hydrogen, argon, helium), and different unique/poisonous gases (fluorine, nitrogen trifluoride, arsine, phosphine, boron trifluoride, diborane, silane, and the listing goes on…)

- Fluids (photoresists, high coats, CMP slurries)

- Photomasks

- Wafer dealing with gear, dicing

- RF Mills

Wafer Fab Gear (WFE) Make the Chips

- These machines bodily manufacture the chips

- 5 firms dominate the business – Utilized Supplies, KLA, LAM, Tokyo Electron and ASML

- These are among the most intricate (and costly) machines on Earth. They take a slice of an ingot of silicon and manipulate its atoms on and under its floor

- We’ll clarify how these machines are used a bit in a while

“Fabless” Chip Firms

- Programs firms (Apple, Qualcomm, Nvidia, Amazon, Fb, and so on.) that beforehand used off-the-shelf chips now design their very own chips.

- They create chip designs (utilizing IP Cores and their very own designs) and ship the designs to “foundries” which have “fabs” that manufacture them

- They might use the chips solely in their very own units e.g. Apple, Google, Amazon ….

- Or they could promote the chips to everybody e.g. AMD, Nvidia, Qualcomm, Broadcom…

- They don’t personal Wafer Fab Gear or use specialised supplies or chemical substances

- They do use Chip IP and Digital Design Software program to design the chips

Built-in Gadget Producers (IDMs)

- Built-in Gadget Producers (IDMs) design, manufacture (in their very own fabs), and promote their very own chips

- They don’t make chips for different firms (that is altering quickly – see right here.)

- There are three classes of IDMs– Reminiscence (e.g. Micron, SK Hynix), Logic (e.g. Intel), Analog (TI, Analog Gadgets)

- They’ve their very own “fabs” however may use foundries

- They use Chip IP and Digital Design Software program to design their chips

- They purchase Wafer Fab Gear and use specialised supplies and chemical substances

- The common value of taping out a brand new modern chip (3nm) is now $500 million

Chip Foundries

- Foundries make chips for others of their “fabs”

- They purchase and combine gear from quite a lot of producers

- Wafer Fab Gear and specialised supplies and chemical substances

- They design distinctive processes utilizing this gear to make the chips

- However they don’t design chips

- TSMC in Taiwan is the chief in logic, Samsung is second

- Different fabs focus on making chips for analog, energy, rf, shows, safe army, and so on.

- It prices $20 billon to construct a brand new era chip (3nm) fabrication plant

Fabs

- Fabs are brief for fabrication vegetation – the manufacturing facility that makes chips

- Built-in Gadget Producers (IDMs) and Foundries each have fabs. The one distinction is whether or not they make chips for others to make use of or promote or make them for themselves to promote.

- Consider a Fab as analogous to a e-book printing plant (see determine under)

- Simply as an writer writes a e-book utilizing a phrase processor, an engineer designs a chip utilizing digital design automation instruments

- An writer contracts with a writer who specializes of their style after which sends the textual content to a printing plant. An engineer selects a fab applicable for his or her kind of chip (reminiscence, logic, RF, analog)

- The printing plant buys paper and ink. A fab buys uncooked supplies; silicon, chemical substances, gases

- The printing plant buys printing equipment, presses, binders, trimmers. The fab buys wafer fab gear, etchers, deposition, lithography, testers, packaging

- The printing course of for a e-book makes use of offset lithography, filming, stripping, blueprints, plate making, binding and trimming. Chips are manufactured in a sophisticated course of manipulating atoms utilizing etchers, deposition, lithography. Consider it as an atomic degree offset printing. The wafers are then minimize up and the chips are packaged

- The plant seems thousands and thousands of copies of the identical e-book. The plant seems thousands and thousands of copies of the identical chip

Whereas this sounds easy, it’s not. Chips are most likely probably the most sophisticated merchandise ever manufactured. The diagram under is a simplified model of the 1000+ steps it takes to make a chip.

Whereas this sounds easy, it’s not. Chips are most likely probably the most sophisticated merchandise ever manufactured. The diagram under is a simplified model of the 1000+ steps it takes to make a chip.

Outsourced Semiconductor Meeting and Take a look at (OSAT)

- Firms that bundle and check chips made by foundries and IDMs

- OSAT firms take the wafer made by foundries, cube (minimize) them up into particular person chips, check them after which bundle them and ship them to the client

Fab Points

- As chips have turn into denser (with trillions of transistors on a single wafer) the price of constructing fabs have skyrocketed – now >$10 billion for one chip manufacturing facility

- One cause is that the price of the gear wanted to make the chips has skyrocketed

- Only one superior lithography machine from ASML, a Dutch firm, prices $150 million

- There are ~500+ machines in a fab (not all as costly as ASML)

- The fab constructing is extremely complicated. The clear room the place the chips are made is simply the tip of the iceberg of a fancy set of plumbing feeding gases, energy, liquids all on the proper time and temperature into the wafer fab gear

- The multi-billion-dollar value of staying at the forefront has meant most firms have dropped out. In 2001 there have been 17 firms making probably the most superior chips. As we speak there are solely two – Samsung in Korea and TSMC in Taiwan.

- On condition that China believes Taiwan is a province of China this might be problematic for the West.

What’s Subsequent – Know-how

What’s Subsequent – Know-how

It’s getting a lot tougher to construct chips which are denser, quicker, and use much less energy, so what’s subsequent?

- As a substitute of creating a single processor do all of the work, logic chip designers have put a number of specialised processors inside a chip

- Reminiscence chips at the moment are made denser by stacking them 100+ layers excessive

- As chips are getting extra complicated to design, which suggests bigger design groups, and longer time to market, Digital Design Automation firms are embedding synthetic intelligence to automate components of the design course of

- Wafer gear producers are designing new gear to assist fabs make chips with decrease energy, higher efficiency, optimum area-to-cost, and quicker time to market

What’s Subsequent – Enterprise

The enterprise mannequin of Built-in Gadget Producers (IDMs) like Intel is quickly altering. Previously there was an enormous aggressive benefit in being vertically built-in i.e. having your personal design instruments and fabs. As we speak, it’s a drawback.

- Foundries have economies of scale and standardization. Fairly than having to invent all of it themselves, they’ll make the most of the whole stack of innovation within the ecosystem. And simply give attention to manufacturing

- AMD has confirmed that it’s doable to shift from an IDM to a fabless foundry mannequin. Intel is making an attempt. They will use TSMC as a foundry for their very own chips in addition to arrange their very own foundry

What’s Subsequent – Geopolitics

Controlling superior chip manufacturing within the twenty first century could nicely show to be like controlling the oil provide within the twentieth. The nation that controls this manufacturing can throttle the army and financial energy of others.

- Making certain a gentle provide of chips has turn into a nationwide precedence. (China’s largest import by $’s are semiconductors – bigger than oil)

- As we speak, each the U.S. and China are quickly making an attempt to decouple their semiconductor ecosystems from one another; China is pouring $100+ billion of presidency incentives in constructing Chinese language fabs, whereas concurrently making an attempt to create indigenous provides of wafer fab gear and digital design automation software program

- Over the previous couple of a long time the U.S. moved most of its fabs to Asia. As we speak we’re incentivizing bringing fabs and chip manufacturing again to the U.S.

An business that beforehand was solely of curiosity to technologists is now one of many largest items in nice energy competitors.

Filed beneath: Gordian Knot Heart for Nationwide Safety Innovation, Know-how |

[ad_2]